Connecting Hyperlink – Press Fit (BS/DIN/ANSI)

The conventional connecting hyperlink for ANSI series detachable chains, also made use of on riveted chains where higher speeds or arduous conditions are encountered. Supplied with two connecting pins riveted into the outer plate, the other outer plate currently being a press fit onto the pins and secured by split pins right after assembly. Press fit connecting backlinks can only be utilised the moment; new hyperlinks will have to normally be made use of to replace dismantled links.

Cranked hyperlinks

Other than the specialized chains wherever the cranked link is an important layout feature, cranked hyperlinks are applied only where the chain length must be an odd amount of pitches. This practice just isn’t advisable; all drives need to, wherever attainable, be intended with adequate general adjustment to make certain the use of an even quantity of pitches throughout the chain. Tend not to USE CRANKED Backlinks ON IMPULSIVE, Remarkably LOADED OR Large Speed DRIVES.

Cranked Link – Slip Fit (BS/DIN) Offset Website link – Slip Match (ANSI)

Just one website link with cranked plates pressed onto a bush and roller assemble on the narrow finish. A clearance match connecting pin (No. 128) is fitted at the wide finish and is secured by a split pin.

Cranked Link Double  (BS/DIN) Two Pitch Offset Website link (ANSI)

(BS/DIN) Two Pitch Offset Website link (ANSI)

Double cranked links are available for many sizes and kinds of chain. The unit includes an inner hyperlink (No. 4), with cranked back links retained permanently in place by a riveted bearing pin. Screw operated extractors break chain by forcing the finish softened bearing pins from the outer website link plates. For other brands of chain, the rivet swell ought to initial be ground away.

Category Archives: Uncategorized

admin

March 5, 2021

Precision Roller Chain, Parts and Connecting Back links

The precision steel roller chain is usually a very productive and versatile means of transmitting mechanical power, which, inside the discipline of industrial applications, has almost wholly superseded all other forms of chain previously used.

Outer Hyperlink – Press Match (BS/DIN) Riveting Pin Link – Press Match (ANSI)

For use with all sizes and types of chain wherever optimum protection is preferred. The website link is supplied with bearing pins riveted into one particular outer plate. The other outer plate is an interference match on the bearing pins, the ends of which must be riveted more than right after the plate is fitted. Press match connecting back links ought to only be utilised as soon as; new backlinks must be made use of to exchange dismantled backlinks. (See ‘Riveting Chain Endless’ for full directions).

Connecting Hyperlink – Slip Match (BS/DIN/ANSI)

A connecting hyperlink supplied with two connecting pins riveted in to the outer plate. The outer plate is actually a clearance fit within the connecting pins and it is  secured in position by a split pin through the projecting finish of each connecting pin.

secured in position by a split pin through the projecting finish of each connecting pin.

Connecting Website link – Slip Fit (BS/DIN/ANSI)

Employed on brief pitch chains only. Supplied with two connecting pins riveted to the outer plate, the clearance fit connecting plate remaining secured by way of a spring clip, No. 27, which snaps into the grooves within the pins.

admin

March 5, 2021

Precision Roller Chain, Components and Connecting Links

The precision steel roller chain is really a highly effective and versatile  implies of transmitting mechanical electrical power, which, within the discipline of industrial applications, has practically fully superseded all other forms of chain previously used. The illustration beneath demonstrates element elements of the outer link and on the inner hyperlink of a uncomplicated roller chain. As illustrated, the precision steel roller chain includes a series of journal bearings held in exact romantic relationship to every other from the constraining hyperlink plates. Each and every bearing includes a bearing pin and bush on which the chain roller revolves. The bearing pin and bush are case hardened to allow articulation below substantial pressures, and to contend with the load carrying pressures and gearing action imparted by way of the chain rollers. All chains are classified according to pitch (the distance amongst the centers of adjacent bearing pins), roller diameter and width among inner plates. Collectively, these dimensions are often called the gearing dimensions, as they determine the kind and width in the sprocket teeth.

implies of transmitting mechanical electrical power, which, within the discipline of industrial applications, has practically fully superseded all other forms of chain previously used. The illustration beneath demonstrates element elements of the outer link and on the inner hyperlink of a uncomplicated roller chain. As illustrated, the precision steel roller chain includes a series of journal bearings held in exact romantic relationship to every other from the constraining hyperlink plates. Each and every bearing includes a bearing pin and bush on which the chain roller revolves. The bearing pin and bush are case hardened to allow articulation below substantial pressures, and to contend with the load carrying pressures and gearing action imparted by way of the chain rollers. All chains are classified according to pitch (the distance amongst the centers of adjacent bearing pins), roller diameter and width among inner plates. Collectively, these dimensions are often called the gearing dimensions, as they determine the kind and width in the sprocket teeth.

Normal back links

The chain components and connecting hyperlinks illustrated are only indicative with the sorts accessible. Please refer for the appropriate product web page for that elements pertinent to personal chains.

They are finish assemblies for use with all sizes and kinds of chain. The unit includes two inner plates pressed on towards the bushes which carry the rollers. (Inner backlinks for use with bush chains have no rollers).

admin

March 4, 2021

STAINLESS STEEL CHAIN

The consolidation of Viking Chains Group into

Connexus Industries has permitted the continuation of the VC Brand of Steel Chains. The VC Brand says top quality manufacturing procedure, and extended services daily life. This productive brand incorporates the next:

WELDED STEEL CHAIN

?  Complete Press Match Rivets

Complete Press Match Rivets

? Parallel Sidebar Holes

? High Top quality Materials & Heat Treating

WELDED STEEL PLUS

? Welded flush on outside eliminates any

interference with sprockets

? Parallel holes for “True-Fit”

? Seamless Barrels eliminate

“Premature Stretch”

WELDED STEEL DRAG CHAIN

? Fully Heat Treated Barrels

? Complete Press Match Rivets

? Parallel Sidebar Holes

? Higher High quality Materials & Heat Treating

DOUBLE LENGTH INFEED CHAINS, SCANNING CHAINS, FLIGHTS, SPROCKETS AND BEDPLATES

? Specifically Constructed to withstand Substantial Speed, Impact applications

? Industry Leader for 25 plus years

? Custom Solutions

SUGAR MILL CHAINS

? Designed for Lengthy Support daily life in Sugar Mill applications

? Heat Treated Stainless Steel, Hard Chrome options available

? Standard and Custom attachments

SPECIALTY CHAINS FOR ALL MARKETS

Mill chain

I’Anco Cast alloy steel and Hadfield manganese steel mill chains are designed for the most severe service applications in wood processing facilities today. They are designed to handle extreme wear, substantial tensile loads and extreme impact. Our ability cast attachments integral to the link eliminates any chance of creating heat affected zones by welding; however, the materials are readily weldable allowing for quick turnaround times for custom attachments. All of our cast links have recessed head and rivet ends offering protection from side wear on the rivets. This also allows us to pour the links with heavier cross sections adding to the overall strength in the chains plus creating larger bearing surfaces to distribute the loads over a larger area reducing the wear on the side bars.

admin

March 4, 2021

STAINLESS STEEL CHAIN

The consolidation of Viking Chains Group into

Connexus Industries has permitted the continuation with the VC Brand of Steel Chains. The VC Brand says good quality manufacturing system, and prolonged service existence. This profitable brand incorporates the following:

WELDED STEEL CHAIN

? Total Press Match Rivets

? Parallel Sidebar Holes

? Substantial Quality Materials & Heat Treating

WELDED STEEL PLUS

? Welded flush on outside eliminates any

interference with sprockets

? Parallel holes for “True-Fit”

? Seamless Barrels eliminate

“Premature Stretch”

WELDED STEEL DRAG CHAIN

? Fully Heat Treated Barrels

? Total  Press Match Rivets

Press Match Rivets

? Parallel Sidebar Holes

? Large High quality Material & Heat Treating

DOUBLE LENGTH INFEED CHAINS, SCANNING CHAINS, FLIGHTS, SPROCKETS AND BEDPLATES

? Specifically Constructed to withstand Higher Speed, Impact applications

? Industry Leader for 25 plus years

? Custom Solutions

SUGAR MILL CHAINS

? Designed for Lengthy Services life in Sugar Mill applications

? Heat Treated Stainless Steel, Hard Chrome options available

? Standard and Custom attachments

SPECIALTY CHAINS FOR ALL MARKETS

Mill chain

I’Anco Cast alloy steel and Hadfield manganese steel mill chains are designed for the most severe service applications in wood processing facilities today. They are designed to handle extreme wear, high tensile loads and extreme impact. Our ability cast attachments integral to the link eliminates any chance of creating heat affected zones by welding; however, the materials are readily weldable allowing for quick turnaround times for custom attachments. All of our cast links have recessed head and rivet ends offering protection from side wear on the rivets. This also allows us to pour the links with heavier cross sections adding to the overall strength with the chains plus creating larger bearing surfaces to distribute the loads over a larger area reducing the wear on the side bars.

admin

March 4, 2021

Chrome steel CHAIN

Built for food applications as well as in spots exactly where wash-down, steam, and

chemical compounds are prevalent.

DRAG CHAIN

Deliver successful implies to express.

sawdust, chips or bark dust. Prolonged

run daily life in slow speed programs.

81X ENGINEERING Course CHAIN

Generally used for sluggish to reasonable pace drives and conveyor programs.

Popular attachments consist of bullnose UHMW, plastic caps, camelbacks,

trimmer lugs and pusher lugs.

AGRICULTURAL Class CHAIN

Intended to resist the cruel

natural environment in the agriculture

market. Long-lasting, with fewer

upkeep.

LEAF CHAIN

Leaf chain is employed for programs that require sturdy flexible linkage for  transmitting movement or elevate.

transmitting movement or elevate.

Energy TRANSMISSION CHAIN

Made to provide a flexible suggests of energy transmission. Offered in the two offset and straight sidebar configuration.

DOUBLE FLEX CHAIN

Intended for conveying apps where bend radius is needed for material move transform of direction.

SHARP Best CHAIN?

Exceptional solution to enhance feed speeds. Available in several tooth profile patterns. Number 1 preference of first machines manufacturers.

WELDED Steel MILL CHAIN

Specifically made to deliver economical suggests to express solution in right now??¥s

most hard materials dealing with programs. Welded attachments can be found in a lot of models.

ROLLER CHAIN

Great for industrial and agriculture applications. Plates and rollers are shot peened and pre-stretched at manufacturing facility for better strength and extended lifetime.

admin

March 4, 2021

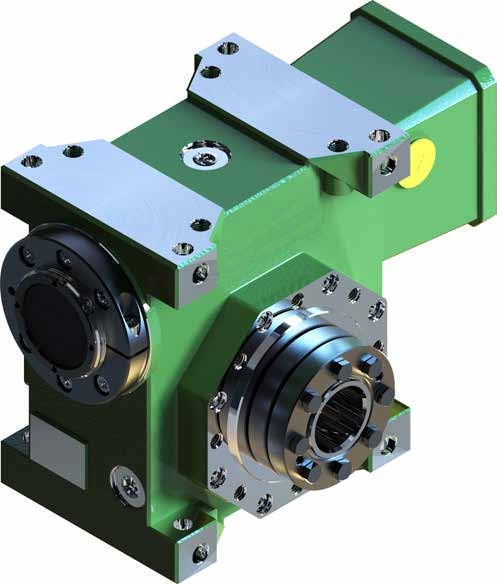

SMR Reducer Specification

one, Output Hubs

Regular or option hubs with metric bores can be found to suit global shaft diameters.

2, Precision High-quality Gearing

Computer system Designed Helical Gear. Powerful Alloy Products for Substantial Load Capability, Situation Carburized for long lifestyle, Ground Profile (some intermediate pinions are shaved), Crown tooth Profile, In Conformance with ISO 1328-1997, 98% Efficiency for per Stage, Smooth Quiet Operation with Teeth in Mesh.

three, Maximum  Capacity Housing Design

Capacity Housing Design

Near Grain Cast Iron Development, Excellent Vibration Dampening & shock Resistance features, Precision Bored and Dowelled to Ensure Accurate In-line Assembly.

4, Solid Alloy Steel Shafts

Solid Alloy Steel, Hardened, Ground on journals, Gear Seatings and Extensions, for Highest Load and Maximum Torsional Loads, Generous Sizes Shaft Keys for Shock Loading and Conform to ISO Standards.

5, Additional Case Lugs (Except H and J Gear Case)

Eliminates the Need for Critical Tightening of Torque arm Bolts, Controls Position of Standard Torque Arm Mounting within Recommended limits.

6, Backstops

Substitute Parts, Anti-run Back Device, Are available on all 13:1 and 20:one Ratio units and do not recommend for 5:one Units.

7, Bearing and Oil seals

Bearing are Adequately Proportioned and Conform to ISO dimension plan, Readily Out there World-wide, Oil seals are Double.

Lipped Garter Spring Type, Ensuring Effective Oil Sealing.

8, Rubberised End Caps

Self sealing Intermediate Cover Plates, to Normal ISO Housing Dimensions.

9, Torque Arm Assembly

For Easy Adjustment of the Belt.

admin

March 3, 2021

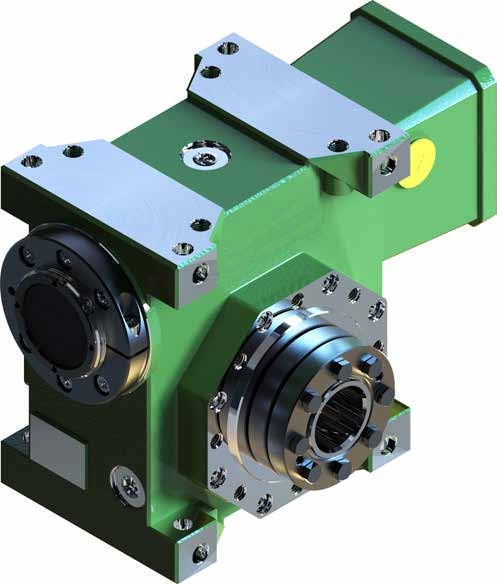

SMR Reducer Specification

one, Output Hubs

Common or different hubs with metric bores can be found to suit international shaft diameters.

2, Precision Good quality Gearing

Laptop Intended Helical Gear. Strong  Alloy Materials for Large Load Capability, Case Carburized for lengthy daily life, Ground Profile (some intermediate pinions are shaved), Crown tooth Profile, In Conformance with ISO 1328-1997, 98% Efficiency for per Stage, Smooth Quiet Operation with Teeth in Mesh.

Alloy Materials for Large Load Capability, Case Carburized for lengthy daily life, Ground Profile (some intermediate pinions are shaved), Crown tooth Profile, In Conformance with ISO 1328-1997, 98% Efficiency for per Stage, Smooth Quiet Operation with Teeth in Mesh.

three, Greatest Capacity Housing Style

Close Grain Cast Iron Construction, Outstanding Vibration Dampening & shock Resistance features, Precision Bored and Dowelled to Ensure Accurate In-line Assembly.

4, Strong Alloy Steel Shafts

Powerful Alloy Steel, Hardened, Ground on journals, Gear Seatings and Extensions, for Optimum Load and Highest Torsional Loads, Generous Sizes Shaft Keys for Shock Loading and Conform to ISO Standards.

5, Additional Case Lugs (Except H and J Gear Case)

Eliminates the Need for Critical Tightening of Torque arm Bolts, Controls Position of Normal Torque Arm Mounting within Recommended limits.

6, Backstops

Option Parts, Anti-run Back Device, Are available on all 13:1 and 20:one Ratio units and do not recommend for 5:1 Units.

7, Bearing and Oil seals

Bearing are Adequately Proportioned and Conform to ISO dimension plan, Readily Readily available World-wide, Oil seals are Double.

Lipped Garter Spring Type, Ensuring Effective Oil Sealing.

8, Rubberised End Caps

Self sealing Intermediate Cover Plates, to Typical ISO Housing Dimensions.

9, Torque Arm Assembly

For Easy Adjustment of the Belt.

admin

March 3, 2021

JDLB Options

Servo worm gear units have 6 forms :45 – 50 – 55 – 63 – 75 – 90, with dual lead worm drive. Left and right flank of worm shaft working with unique lead angle creating tooth thickness gradual adjust. To ensure you can move worm shaft

and change backlash.

JDLB Applications

Precision rotary motion

— Lowering the noise and vibration that is certainly triggered through the load change and also the

alter of cutting force.

— cutting down the noise and impact that’s triggered from the corotation and reverse.

— By minimizing worm abrasion.

— Escalating worm output response velocity.

Precision Indexing device

— CNC machine, assembly line, cutting machine, transmission lines, etc.

— Indexing gadget, correct studying mechanism call for correct motion

events.

Velocity modifying conditions.

— Reducing the noise and the effect that may be caused by pace change.

— Minimizing the worm abrasion that is triggered by velocity adjustments.

JDLB Make decision

The next headings consist of data on critical factors for

assortment and accurate utilization of gearbox.

For specific data to the gearbox array, see the appropriate chapters.

EFFICIENCY

Efficiency is a parameter which features a main influence on the sizing of certain applications, and in essence will depend on gear pair design components. The mesh data table on webpage 9 displays dynamic efficiency (n1=1400)and static efficiency values.

The mesh data table on webpage 9 displays dynamic efficiency (n1=1400)and static efficiency values.

Understand that these values are only accomplished immediately after the unit continues to be run in and it is on the working temperature.

admin

March 3, 2021

JDLB series high precision worm gear is an great substitute for

precision planetary gearbox, the equipment manufacturer can

considerably lower the cost of making use of precision planetary gearbox.

Hollow output with shrink disc, high precision, for quick integration.

Output with keyway, hassle-free set up, quick integration.

Strong shaft output (single, double), high stiffness, standard solution.

The designer’s perfect option would be to rotate 90 degrees to install the servo motor drive methods.

Worm shaft in series might be driven by a single motor to achieve synchronous output of several worm wheels. It’s been applied in

automated polishing cell phone shell as well as other equipments.

Optimized make contact with pattern

* State-of-the-art processing engineering and precision assembly to guarantee the right meshing from the tooth and lower get hold of anxiety of your tooth surface.

* Distinctive worm wheel bronze alloy makes the teeth have substantial power and fantastic dress in resistance.

* That has a substantial ratio of tooth surface get in touch with, worm wheel just isn’t straightforward to wear, it could preserve the locked backlash.

Optimized adjustment construction

* Promptly  setting backlash.

setting backlash.

* Larger stiffness and precision.

* Patent construction.

Maintenance free of charge

* High effectiveness synthetic lubricant.

* Closed construction, no need to have to replace lubricant oil.

Speedily set up servo motor

* Substantial stiffness and very low inertia coupling for servo motor.

* Various flanges is often matched using the servo motor.

Installed two taper roller bearings with which have longer support lives.

* Eliminates worm shaft alignment complications.

* Bearing pre-tight installation, with larger support stiffness.

Worm shaft working with Taper roller bearings.

* Installed two taper roller bearings with which have longer services lives.

* Eliminates worm shaft alignment problems.

* Bearing pre-tight set up, with larger assistance stiffness.

Output torsional backlash out there in two ranges:

* Ultra precision: 1 arc minute for that most demanding applications.

* Precision: two to 4 arc minutes a good compromise cost and good quality.

Housing with gravity casting

* Substantial power Aluminum Alloy casting and heat treatment.

* Superior rigidity and reduced bodyweight.

* Lovely shape and Good climate resisting residence.