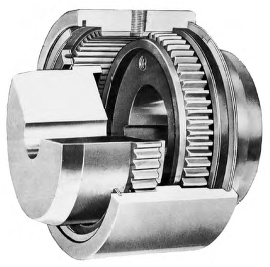

Why Coupling Grease?

Adequate lubrication is important for satisfactory gear coupling operation. Gear Coupling Grease is particularly created for gear coupling applications to improve coupling daily life although significantly reducing upkeep time. Its large viscosity base oil and tackifier mix to help keep the grease in place and stop separation and it’s in total  compliance with NSI/AGMA 9001-B97 lubrication recommendations.

compliance with NSI/AGMA 9001-B97 lubrication recommendations.

Coupling Grease is dark brown in shade and produced with a lithium soap/polymer thickener, which has superior resistance to oil separation when subjected to large centrifugal forces ordinarily uncovered in couplings. Bearing or general objective greases have a tendency to separate and lose effectiveness on account of substantial centrifugal forces to the different ingredients at high rotational speeds. These large centrifugal forces encountered in couplings separate the base oil from the thickeners. Heavy thickeners, which have no lubrication characteristics, accumulate inside the gear tooth mesh area resulting in premature coupling failure. Gear Coupling Grease is intended to remarkably resistant to centrifugal separation in the oil and thickener, which makes it possible for the lubricant to get utilized for any fairly extended period of time.

One of several secrets towards the success of Gear Coupling Grease would be the variable consistency throughout the functioning cycle in the application. The consistency of our gear coupling grease adjustments with all the working ailments. Working in the lubricant beneath real support circumstances causes the grease to develop into semi-fluid, functionally solash lubricating the dress in surfaces in the coupling. Because the grease cools, it returns to your original consistency, therefore stopping leakage.

Gear Coupling Grease is available from stock in 14 oz. cartridges, 1 lb. and 5 lb. cans.

Functions

Minimizing of coupling wear

Resistance to water washing

Corrosion and rust protection

Higher load carrying abilities

Extended relubrication frequency

Use at temperatures up to 325° F

Staying in place beneath higher speeds

Resistance to centrifugal separation

Reduction in down time & upkeep cost

Gear Coupling Grease has a consistency which overlaps the NLGI grades 0 and 1. This grease is specially formulated that has a lithium/polymer thickener and fortified with corrosion, oxidation, extreme pressure, and a effective rust inhibitor additive package.